About “PLANTAXIS®”

A novel facility management solution based on the opinions of on-site personnel

A next-generation facility management service backed up by experience of plant maintenance

A facility management service resulted from the new perspective of an engineering company that is familiar with the “actual problems” of facility maintenance.

The problems that facility maintenance personnel actually experience include:

Not knowing where to find the necessary facility information!

The inspection data includes too many omissions and oversights and thus cannot be used when needed most!

We do wish to renovate the facility but the field study alone would cost too much and be too time consuming!

We forgot to order some supplies and thus the process has to be delayed!

We don’t know how to utilize the inspection/failure data!

We have identified a way of solving those problems using the cloud service

PLANTAXIS®, which can be used to connect facilities, people and data in 3D space.

- Intuitively

usable - All facility data

centrally controlled

via 3D User

Interfaces - Reliable

support system

Expected results

Downtime

20%reduction

Active use of inspection data enables possible failures to be predicted and thus prevented. Sudden failures can be quickly addressed and resulting downtime reduced, and thus the facility utilization ratio increased.

Operating hours

25%reduction

The time required for field studies, documentation, reports, troubleshooting, etc. can be significantly reduced. Manpower used in maintenance work can be intensively assigned to more high value-added operations.

Data input rate

100%

All information of inspections, construction work, etc. is stored in a digital format. The UIs facilitate data input, thus, ensuring it is recorded and stored, thereby, linked and then utilized.

Easy-to-start and easy-to-operate

Accessible with normal PCs and tablets anytime, anywhere.

No initial cost required. An annual-subscription-based cloud service whose functions get updated as appropriate.

No installation work necessary. The service is ready as soon as the plant has been 3D scanned and registered.

Strong points of PLANTAXIS®

Strong Point 1

Intuitively usable 3D Digital Plant

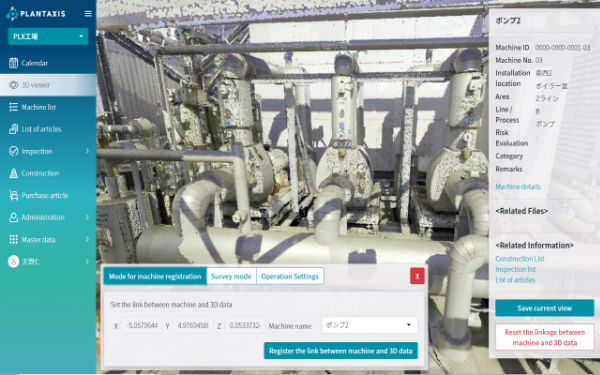

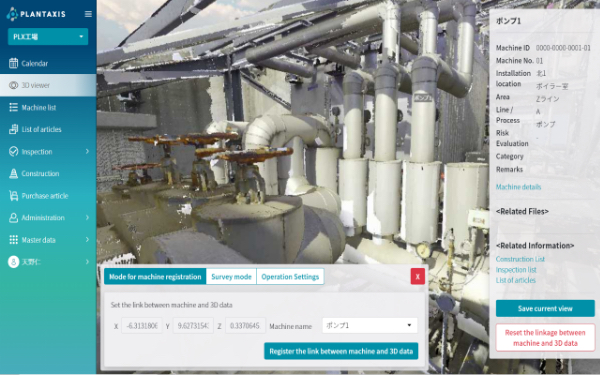

For PLANTAXIS®, we have developed a “3D Digital Plant” that enables 3D scanning of plants, with the data then being used in the operating screen.

Data on a 3D scanned plant is stored on the Cloud as groups of fine points (point clouds) with their positional relationship maintained. With just one click of the reproduced 3D digital image of a piece of equipment in the plant, you can retrieve all the information about it, for example, inspection data and drawings.

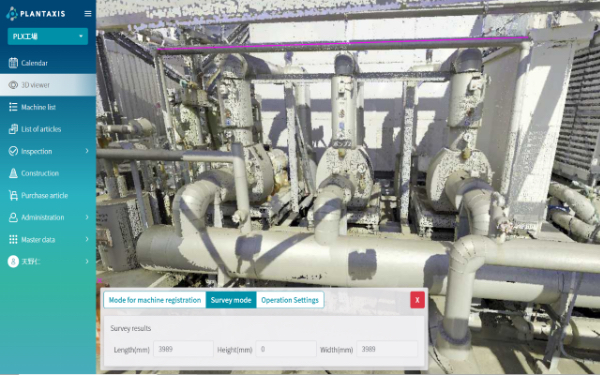

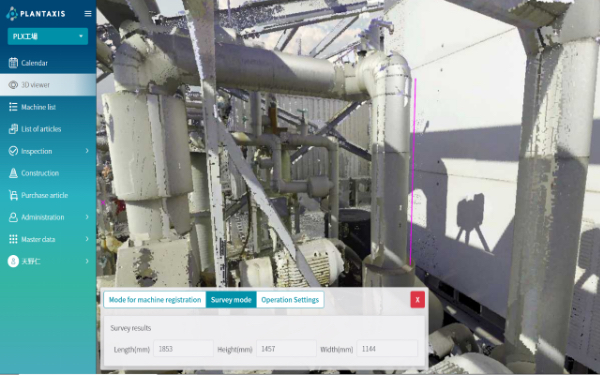

Field studies and measurements also can be made from your desk, which significantly reduces the time and cost of preparing for any construction work.

Strong Point 2

Manpower support to ensure continuation and full usage

The biggest hurdle with installing a facility management system is the endless data entry work. And any management system, needless to say, is of no use without accumulating data.

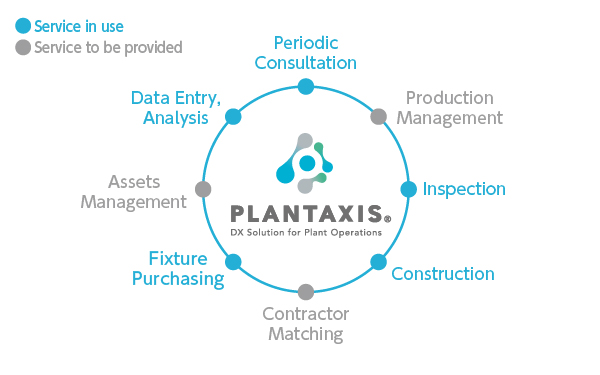

In association with PLANTAXIS®, we recommend the use of a data entry service to reduce your workload and a periodic updating service for your 3D scan data. In addition, a consultation service is available through our engineers who will analyze your maintenance data and propose future action plans in periodical face-to-face meetings.

Strong Point 3

Next-generation plant operation platform connects data

PLANTAXIS® is a plant operation platform that coordinates the facility with the necessary information, personnel, location, and time.

It can also be used to share information between many business bases, and to enhance cooperation within the plant and control production, with the aim of ensuring seamless flow and use through the visualization of the necessary plant operation information. New functions will be systematically added to thereby achieve newer and better plant operations.

Capabilities of PLANTAXIS®

Desk-based field studies

Field studies and measurements in elevated places or clean rooms can be part of desk-based work. This both accelerates the work and reduces the cost.

Inspection result data is now usable!

Inspection results can be input using a tablet on-site. The results can be quickly shared with the Engineering Department and a sign of a failure is quickly identified. We could thereby prevent the failure!

The use of 3D data reduces both the time and cost of construction work.

PLANTAXIS® 3D digital plant can be used to perform desk-based field studies, and then to store the measurements results. This then reduces both the necessary time and cost of construction plans!

Immediately find and purchase items associated with individual equipment.

Items linked to the equipment in advance can be easily selected and purchased. This significantly reduces the time needed for the purchase and helps eliminate wasted time, for example because of mistaken orders.

The data entry service of PLANTAXIS® for more reliable data entry

All the data can be fully input without wasting an employee’s time. The trend of the values, previously hidden, can now be seen!

Periodic Consultation Service Manage a plant based on a PDCA system for improvement!

Data analysis by maintenance engineers enables concrete improvement measures to be reflected in the plan. Now, we can ensure the PDCA cycle is used in facility maintenance.